Ever bite into a homemade french fry only to find it sadly limp instead of crispy? You’re not alone. While restaurant fries snap with that perfect crunch before giving way to a fluffy interior, home versions often fall disappointingly flat. The difference isn’t just luck or fancy equipment—it’s science, technique, and a few industry secrets that restaurants don’t advertise on their menus.

Double-Frying Creates Magic Texture

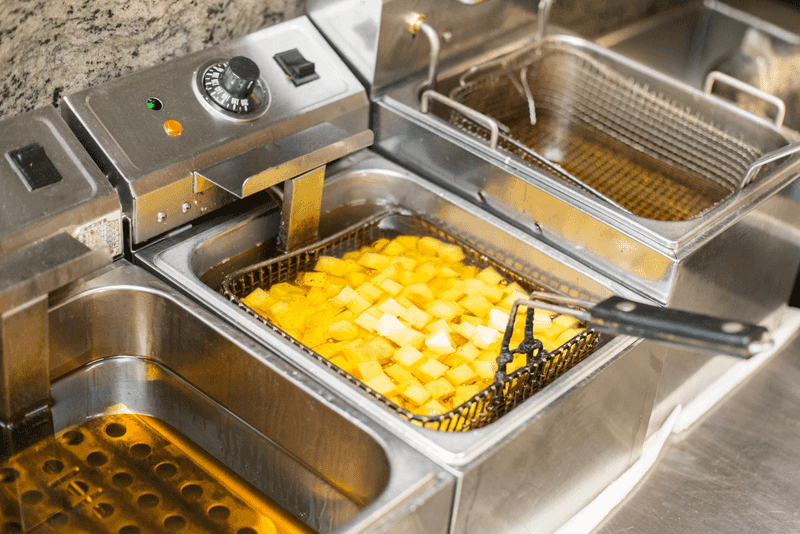

Restaurant kitchens don’t just drop potatoes into hot oil once and hope for the best. They use a two-stage frying method that transforms ordinary spuds into crispy perfection. The first dip at around 325°F cooks the inside without much browning, essentially par-cooking the potato.

After a brief rest, they’re plunged back into hotter oil (375°F or above) to develop that crackling golden shell. This resting period between fries is crucial—it allows moisture to escape from the first cook, setting up the exterior for maximum crispiness.

Most home cooks skip this vital two-step dance, resulting in fries that never quite reach their crispy potential. Your single-fried potatoes simply can’t develop the same structural integrity that makes restaurant fries stand at attention.

Commercial Fryers Maintain Perfect Heat

Your home stovetop setup faces a major disadvantage: temperature control. Restaurant fryers pack serious power—often 1,500+ watts with specialized heating elements and oil circulation systems. When cold potatoes hit their oil, the temperature barely budges.

Meanwhile, your home pot or countertop fryer suffers a dramatic temperature drop when food goes in. This temperature roller coaster means your fries absorb more oil rather than quickly forming a seal. They steam instead of fry, resulting in that disappointingly soggy texture.

Restaurants also filter their oil continuously, removing those burnt bits and food particles that affect flavor and crispness. Fresh, clean oil creates cleaner-tasting, crispier fries that home cooks struggle to replicate without commercial filtration systems.

Premium Potato Varieties Make All The Difference

Not all potatoes are created equal in the french fry world. Restaurants carefully select high-starch varieties like Russet Burbanks or Kennebecs specifically bred for frying. These potatoes naturally contain the perfect starch-to-moisture ratio that creates that magical fluffy interior.

The average grocery store potato grab-bag doesn’t cut it. Many home cooks unknowingly use waxy potatoes or all-purpose varieties that simply can’t achieve the same texture. These lower-starch options hold too much moisture and won’t develop that distinctive crispy shell.

Restaurant suppliers provide consistent, aged potatoes with ideal sugar levels for browning. Your potatoes might be too fresh (yes, that’s a thing) or stored improperly, causing inconsistent results that leave you wondering why your fries never measure up.

The Secret Soak That Changes Everything

Restaurant chefs know that great fries begin long before they hit the oil. They soak cut potatoes in cold water—sometimes with a splash of vinegar—for 30 minutes or longer. This seemingly simple step removes excess surface starch that would otherwise prevent proper crisping.

Many home cooks skip this crucial preparation or give potatoes just a quick rinse. Without proper soaking, the surface starch gelatinizes when fried, creating a barrier that traps moisture and ruins crispiness. The vinegar trick works by strengthening cell walls, helping fries hold their shape under high heat.

After soaking, professional kitchens thoroughly dry their potatoes—another step home cooks often rush. Even small amounts of water cause dangerous oil splatter and prevent that golden crust from forming properly.

Oil Quality And Perfect Seasoning Timing

Contrary to what you might expect, brand-new oil doesn’t make the best fries. Restaurants often use partially broken-down oil that’s been through a few cooking cycles. This slightly degraded oil bonds more effectively with potato starch, creating superior crispiness.

The timing of seasoning is another professional secret. Restaurants salt their fries immediately after they leave the fryer—within seconds—while a microscopic layer of steam still surrounds each fry. This perfect moment helps the salt adhere evenly rather than falling off.

Most home cooks either season too early (in the raw stage) which draws out moisture, or too late when fries have cooled and salt won’t stick properly. This precise seasoning window makes restaurant fries taste perfectly salted throughout, not just on the surface.

Factory-Engineered Frozen Fries Beat Fresh

Here’s the industry’s biggest secret: most restaurant fries aren’t made from scratch. They use specially engineered frozen products designed in food labs to perform perfectly every time. These aren’t your average grocery freezer fries.

Commercial frozen fries undergo pressure-cooking, precise blanching, flash-freezing, and sometimes coating with modified starches or invisible batters. Some are even sprayed with sugar solutions to enhance browning. This manufacturing process ensures consistent results regardless of who’s working the fryer.

Your fresh-cut potatoes, while wholesome, simply can’t compete with this food science. Major suppliers like Lamb Weston spend millions perfecting fries that maintain their crisp exterior and fluffy interior through freezing, shipping, and final cooking—an advantage your kitchen can’t match without industrial equipment.